- Repair robotstudio installation how to#

- Repair robotstudio installation manual#

- Repair robotstudio installation download#

- Repair robotstudio installation windows#

Repair robotstudio installation how to#

The course goal is to teach students how to operate and program the robot using the teach pendant. Use, describe and edit paint process instructions Load, save, and edit basic programs using the paint teach pendant Identify and use the paint teach pendant The course goal is to teach students how to operate and modify the robot programs using the paint teach pendant. Manually execute portions of a basic program Use input and output instructions in a basic program Modify movement instructions in a basic program Load, save, and edit basic programs using the teach pendant

Repair robotstudio installation manual#

Run the robot system in manual mode and automatic mode Practice all areas of safety as they pertain to the robot Positioning the robot by use of joystick control Instruction identification and program flow Operating controls and indicators on the robot controller Safety precautions used while programming and program execution The goal of this class, available for all robot types, is to provide students who have little or no prior exposure to robot technology, knowledge and confidence on how to operate the robots using the teach pendant. S4/S4C/S4C+ - 2 days – Course Code: US302 Robot Operations for Material Handling, Arc Welding, LaserCutting, Spot Welding It is self paced and must be taken within 30 days of enrollment.

Student profile: This course is intended for personnel responsible for starting and operating the robot.Ĭourse duration is 5-6 hours.

Demonstrate how to save robot information Demonstrate how to use the input and output instructions in a basic program Modify movement instructions in a basic program Interpret and respond to event messages The goal of this Web Based Training is to teach students how to operate the robot and modify positions using the FlexPendant.Ĭourse objectives: After successfully completing the course, the participant should be able to: The certification exam is administered by a Certified ABB SafeMove Pro Instructor.Online Interactive Web Based Training Robot Operationsįor Material Handling, Arc Welding, LaserCutting, Spot Welding Each student who successfully completes and demonstrates the requirements for certification with a passing rate of 75% or better, will receive a certificate to that effect.

Repair robotstudio installation download#

To be able to download and configure safety zones and safe Ethernet communications. The goal of the course is to get an understanding of SafeMove 2 nd generation.

Repair robotstudio installation windows#

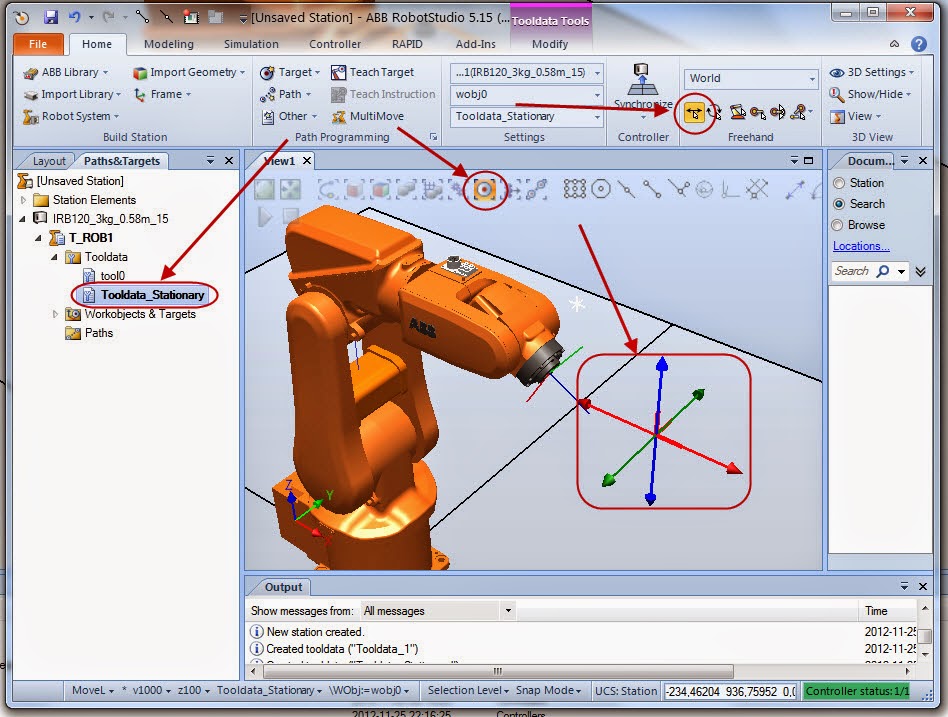

Understanding of Windows or computer programming is helpful RobotStudio Online and robot operation is helpful Robot Operations for Material Handling (US419) or Programming I for Material Handling (US420) is recommended Student profile: This course is intended for Confirm the proper operation of the configuration

Verify the operation of a safety output Describe the need for a drive module key Verify the contact for the limit switch override is plugged or not strapped

Verify a category 0 stop opens the safety relays Describe wiring procedures for the panel unit inputs Describe wiring procedures for a safety I/O block Review the capabilities and limitations The certification exam is administered by a Certified ABB SafeMove Instructor.Ĭourse objectives: After successfully completing the course, the participant should be able to: This course was designed to teach students how to ensure and configure a high safety level in the robot system using the advanced features of the SafeMove option.

0 kommentar(er)

0 kommentar(er)